Agribusiness, Agriculture, Veterinary Medicine, Cassava, Garri, food security, Agritech and the Red Meat Value Chain.

Saturday, July 22, 2017

High levels of antibiotic-resistance in Indian poultry farming raises concerns.

High levels of antibiotic-resistance in Indian poultry farming raises concerns.A new study from India raises questions about the dangers to human health of farming chicken with growth-promoting antibiotics -- including some of the same drugs used in raising millions of chickens in the United States and worldwide.

The study, led by researchers from the Center for Disease Dynamics, Economics & Policy (CDDEP) and published in Environmental Health Perspectives, found high levels of antibiotic-resistant pathogens in chickens raised for both meat and eggs on farms in India's Punjab state.

The study has serious implications, not only for India but globally, as Overuse of antibiotics in animal farms endangers all of us. We must remove antibiotics from the human food chain, except to treat sick animals, or face the increasingly real prospect of a post-antibiotic world.more

Aquaponics at Home: A Modern Farmer Review of Turnkey Aquaponics Systems for All Levels.

Aquaponics at Home: A Modern Farmer Review of Turnkey Aquaponics Systems for All Levels. Aquaponics—an environmentally-friendly mash-up of aquaculture and hydroponics—is just beginning to take off at a commercial level. But for homesteaders and hobbyists, it’s more feasible than ever to raise catfish and tomatoes together, whether in your garden, greenhouse, or a sunny window. Poopy fish water provides irrigation and nutrients to the produce, which in turn filter the water for the fish.

more

more

more

more

The Amazing New Way to Grow Tomatoes: In Tomato Waste.

The Amazing New Way to Grow Tomatoes: In Tomato Waste. Closed-loop systems, in which waste is used as a nutrient (usually) could well be one of the futures of farming: The goals of minimizing waste and optimizing energy use are rubrics that are becoming increasingly essential. But here's one we haven't heard of before, at least not in quite this way: turning tomato waste into a medium for growing tomatoes.

A new study out of New Zealand and published in the journal HartScience, comes up with a way to reuse green waste in a hydroponic system—and even better, that waste can come from the crop itself.

There are two main concepts to understand here before you can grasp exactly why this is such an interesting idea. The first is biochar, which is basically charcoal created from “green waste,” which is exactly what you think it is. Charcoal is created through heat in an environment without oxygen; often that’s done by burying. The biochar in this study comes from the waste of tomato plants (stems, roots, leaves).

The other concept is the substrate. In a hydroponic system, when a plant is planted in what’s basically a moving stream of water in which nutrients are dissolved, the substrate is a porous bit of…something…that holds the plants in place. Most commonly the substrate is spun rock (a.k.a. rock wool), which is basically cotton candy made of rock. Sawdust is also a pretty popular substrate. more

How to make biochar and increase soil fertility.

How to make biochar and increase soil fertility. For hundreds of years, rain forest farmers have figured out that you can enrich soil with biochar: charcoal, basically. Wet vegetation is burned, producing little bits of charcoal, which are ground into the soil. Eventually, this creates an incredibly rich,fertile soil.

In only the past few years, researchers at universities around the world have realized that the Amazonian technique is replicated in various forms around the world, including West Africa. This new study, led by researchers at the University of Sussex, analyzed 177 sites in Liberia and Ghana and proved that biochar additions, practiced for centuries in these areas, have increased the carbon levels in the soil by two to three times.

By living in villages in these countries, researchers described the techniques: ash and bones, along with kitchen waste, are recycled back into the soil.

The press release for the study says the practice could help mitigate climate change. What they mean by that is that the biochar method transfers carbon to the soil, reducing the amount of carbon dioxide released into the atmosphere.

The infamous slash-and-burn method, in which material like trees and plants are simply burned in open fires, transfers a very small percentage of carbon to the soil, releasing much of it into the atmosphere in the form of carbon dioxide. But slash-and-char, in which wet vegetation under a layer of straw is burned into charcoal, is much more efficient, transferring almost half of its carbon content into the soil.more

How to process mango to prevent post-harvest losses.

In central Kenya, the Kambiti East Mango Self Help Group is using clean energy drying technology to reduce post-harvest waste and access new markets for a stronger community economy.

Samuel is one of fifteen mango farmers in Kambiti East Mango Self Help Group, located in Murang'a County in central Kenya. Formed in late 2013, this group came together with the help of a local community-based organization (CBO) after struggling to find a market for their fruits. The project centered on decreasing the amount of post-harvest losses by sun drying their mango into mango leather.

Samuel Munguti examines a handful of dried mangoes in Kambiti, Kenya.

In 2015, Kambiti joined YieldWise – an initiative of the Rockefeller Foundation and implemented by TechnoServe in Kenya – with the aim of training more than 20,000 farmers on post-harvest loss prevention techniques, increasing market demand for mango by linking farmers to new buyers and finance, and piloting technologies to improve the storage and shelf life of mango. Through YieldWise, Kambiti's farmers participated in hands-on agronomy trainings to improve the quality of their mangoes. They trained us on how to take care of our mango trees, how to prune, how to harvest and they taught us how to use these fly traps.

TechnoServe also connected Kambiti with Village Industrial Power (VIP), a social enterprise startup commercializing innovative clean-energy solutions for rural industries and communities throughout sub-Saharan Africa. As part of a pilot project, VIP provided Kambiti with a mobile power plant, valued at roughly $17,000, which uses agricultural waste as fuel, creating thermal, electrical and mechanical energy to transform crops into higher value products. Super-heated steam produced by this power plant dries these mangoes at record pace, significantly decreasing the amount of loss during the drying process. In fact, 30 kgs of mangoes can be dried within nine hours, whereas sun drying the same weight previously took 48 hours. more

Samuel Munguti examines a handful of dried mangoes in Kambiti, Kenya.

In 2015, Kambiti joined YieldWise – an initiative of the Rockefeller Foundation and implemented by TechnoServe in Kenya – with the aim of training more than 20,000 farmers on post-harvest loss prevention techniques, increasing market demand for mango by linking farmers to new buyers and finance, and piloting technologies to improve the storage and shelf life of mango. Through YieldWise, Kambiti's farmers participated in hands-on agronomy trainings to improve the quality of their mangoes. They trained us on how to take care of our mango trees, how to prune, how to harvest and they taught us how to use these fly traps.

TechnoServe also connected Kambiti with Village Industrial Power (VIP), a social enterprise startup commercializing innovative clean-energy solutions for rural industries and communities throughout sub-Saharan Africa. As part of a pilot project, VIP provided Kambiti with a mobile power plant, valued at roughly $17,000, which uses agricultural waste as fuel, creating thermal, electrical and mechanical energy to transform crops into higher value products. Super-heated steam produced by this power plant dries these mangoes at record pace, significantly decreasing the amount of loss during the drying process. In fact, 30 kgs of mangoes can be dried within nine hours, whereas sun drying the same weight previously took 48 hours. more

Samuel Munguti examines a handful of dried mangoes in Kambiti, Kenya.

In 2015, Kambiti joined YieldWise – an initiative of the Rockefeller Foundation and implemented by TechnoServe in Kenya – with the aim of training more than 20,000 farmers on post-harvest loss prevention techniques, increasing market demand for mango by linking farmers to new buyers and finance, and piloting technologies to improve the storage and shelf life of mango. Through YieldWise, Kambiti's farmers participated in hands-on agronomy trainings to improve the quality of their mangoes. They trained us on how to take care of our mango trees, how to prune, how to harvest and they taught us how to use these fly traps.

TechnoServe also connected Kambiti with Village Industrial Power (VIP), a social enterprise startup commercializing innovative clean-energy solutions for rural industries and communities throughout sub-Saharan Africa. As part of a pilot project, VIP provided Kambiti with a mobile power plant, valued at roughly $17,000, which uses agricultural waste as fuel, creating thermal, electrical and mechanical energy to transform crops into higher value products. Super-heated steam produced by this power plant dries these mangoes at record pace, significantly decreasing the amount of loss during the drying process. In fact, 30 kgs of mangoes can be dried within nine hours, whereas sun drying the same weight previously took 48 hours. more

Samuel Munguti examines a handful of dried mangoes in Kambiti, Kenya.

In 2015, Kambiti joined YieldWise – an initiative of the Rockefeller Foundation and implemented by TechnoServe in Kenya – with the aim of training more than 20,000 farmers on post-harvest loss prevention techniques, increasing market demand for mango by linking farmers to new buyers and finance, and piloting technologies to improve the storage and shelf life of mango. Through YieldWise, Kambiti's farmers participated in hands-on agronomy trainings to improve the quality of their mangoes. They trained us on how to take care of our mango trees, how to prune, how to harvest and they taught us how to use these fly traps.

TechnoServe also connected Kambiti with Village Industrial Power (VIP), a social enterprise startup commercializing innovative clean-energy solutions for rural industries and communities throughout sub-Saharan Africa. As part of a pilot project, VIP provided Kambiti with a mobile power plant, valued at roughly $17,000, which uses agricultural waste as fuel, creating thermal, electrical and mechanical energy to transform crops into higher value products. Super-heated steam produced by this power plant dries these mangoes at record pace, significantly decreasing the amount of loss during the drying process. In fact, 30 kgs of mangoes can be dried within nine hours, whereas sun drying the same weight previously took 48 hours. more

HOW TO GROW A HEALTHY MANGO.

HOW TO GROW A HEALTHY MANGO. As farmers from South Asia to East Africa to Latin America can attest, there is a lot of know-how and hard work behind those sweet and juicy fruits.

Packed with vitamins, antioxidants and fiber, the mango is known for its health benefits. But before it ever reaches your shopping cart, what does it take to grow, store and transport a healthy mango?

Farmers like Annaziatta Masiku, who depend on mangoes for income, often struggle to grow healthy, high-quality fruit in the face of pests, disease and severe weather conditions. Even after harvesting, they can lose a significant share to spoilage due to improper storage or a lack of reliable buyers.

Anna didn't start mango farming until early 2006, when she planted 50 mango trees. As a new mango farmer, Anna lacked knowledge on mango best practices to keep her trees healthy and producing high yields. While Anna was aware of the importance of pruning, she often used a machete to trim her mango trees’ branches. In addition, she lacked key information on fertilizers and pesticides that would reduce post-harvest losses. "After pruning, I didn't know how to dispose of the waste so I would leave it on the ground which resulted in a buildup of weevils which would destroy the fruit," she said.

In May of 2016, Anna joined YieldWise, a program funded by the Rockefeller Foundation and implemented by TechnoServe in Kenya, with the aim of training more than 20,000 farmers on post-harvest loss prevention techniques, increasing market demand for mango by linking farmers to new buyers and finance and piloting technologies to improve the storage and shelf life of mango. more

THE BUSINESS SIDE OF CASHEW.

THE BUSINESS SIDE OF CASHEW.The MozaCajú project teaches cashew farmers in northern Mozambique improved commercialization techniques to boost profits from their harvest.

Cashew farmers in Mozambique like Alda Filomena André work hard all year to secure a good harvest from their cashew trees. She and her husband have a farm of several hundred trees in the northern province of Cabo Delgado, where a significant portion of the cashew production in the country occurs.

In Mozambique, January and February is the time for farmers like Alda to plant new cashew seedlings. In March they are pruning and cleaning their trees. In June and July, they treat the trees for protection from pests and disease. In September they clean them again in preparation for the harvest. Finally, by late October the harvest season starts, lasting through December.

After the harvest comes perhaps the most important stage – commercialization.

Commercialization is the process of making a harvest available on the market, from the initial collection, storage and aggregation all the way through the final sale of the product. For cashew farmers like Alda, it is the time when they can finally reap the benefits from cultivating cashew. They may work hard all the way up to harvesting the cashew from the trees, but if they do not succeed at commercialization then they will not earn a good profit.

Traditionally, cashew farmers in northern Mozambique harvest and sell their cashew nuts all at once. Most commonly, a buyer – some local trader perhaps working alone or on behalf of a factory or warehouse – will come to a cashew producing community with a large scale and will buy as much raw cashew nut as the farmers are willing and able to sell at that time, without much negotiation.

Since 2014, MozaCajú, a three-year project funded by USDA and implemented by TechnoServe that connects Mozambican smallholder cashew farmers to markets and factories, has been training cashew farmers in the three northern provinces of Cabo Delgado, Nampula and Zambézia on commercialization techniques in order to fill the gap in knowledge and information that has prevented them from maximizing their profits. These trainings are organized into sessions on My Cashew Business (O Meu Negocio de Caju), which covers all aspects of commercialization.

The training is given first to promoters, farmers who are known and trusted in their communities and are selected according to specific criteria. These promoters then disseminate the knowledge and information to other cashew farmers in their community, who are formed into groups of 20 to 30 farmers each.

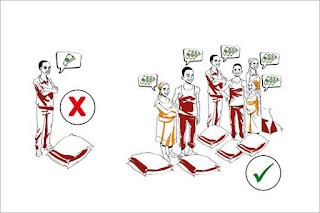

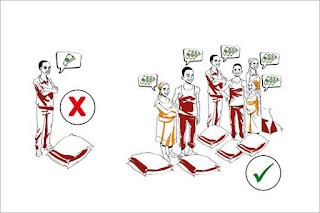

A drawing from the MozaCajú Field Manual encourages farmers to sell their cashew in groups in order to negotiate prices. more

A drawing from the MozaCajú Field Manual encourages farmers to sell their cashew in groups in order to negotiate prices. more

A drawing from the MozaCajú Field Manual encourages farmers to sell their cashew in groups in order to negotiate prices. more

A drawing from the MozaCajú Field Manual encourages farmers to sell their cashew in groups in order to negotiate prices. more

Subscribe to:

Posts (Atom)

Agribusiness ideas.

Popular Posts

-

Five ways agriculture could benefit from artificial intelligence. Agriculture is the industry that accompanied the evolution of humanity ...

-

Climate change may slowly starve bamboo lemurs.Researchers provide evidence to suggest that as Earth's climate changes, bamboo lemurs ...

-

Scientists hope using dogs could revolutionise how malaria is detected, enabling doctors to identify it quickly and without invasive ...

-

. The risk of diabetes,stroke and cancer are reduced with intake of bananas. The ripe,unripe and over-ripe bananas play vital roles in h...

-

A research by Eindhoven University of Technology have come up with a super innovation where artificial leaves mimic natural counterpa...

-

Funding opportunities for agricultural projects. International Tropical Timber Organization — Freezailah Fellowships 2017. ITTO makes grant...

AGRIBUSINESS EDUCATION.

Translate

I-CONNECT -AGRICULTURE

AGRIBUSINESS TIPS.

AGRIBUSINESS.

The Agriculture Daily

veterinarymedicineechbeebolanle-ojuri.blogspot.com Cassava: benefits of garri as a fermented food. Cassava processing involves fermentation which is a plus for gut health. The fermentation process removes the cyanogenic glucosides present in the fres...